Advantage Puck Capabilities for Simplifying Production:

Advantage Puck specializes in the custom design of injection-molded carriers, along with puck loading and unloading and puck conveying and washing. A partnership with Advantage Puck ensures a smooth production line process using:

- Engineering and design using SolidWorks® software

- 3-D design

- 3-D rapid prototyping of pucks for every product

- Minimal lead time from concept to production

- Laser engraving to avoid confusion during production setup

- Extensive inventory of existing pucks

- In-house tool shop and toolmaker

- Experienced injection-molding staff

- Fast turnaround and expedited delivery

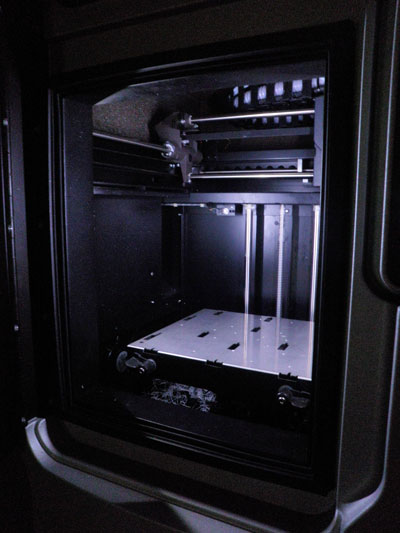

FDM Rapid Prototyping

Reduce tooling costs and minimize design revisions using Advantage Puck’s inexpensive 3-D prototyping. Advantage Puck’s FDM prototypes use a rigid ABS material that is tough enough to test, optimizing each puck early in the design cycle. Sample bottles can also be created using a 3-D file for customers who do not have samples. Advantage Puck creates custom 3-D molded products, not only pucks. For more information and to begin discussing requirements and creating a prototype with or without a 3-D file, contact Advantage Puck at 814.664.4810.

Custom Molding

Advantage Puck specializes in the design and creation of custom-molded carriers, but also partners with clients for full-service design and production of a wide variety of injection-molded products and prototypes. Advantage Puck’s full-time in-house toolmaker and engineering staff use the most current SolidWorks software for custom, 3-D part deign.

Other Great Services from Advantage Puck:

- In-house materials and special order resins

- Large color selection

- Master unit molds to minimize tooling costs

- No minimum quantity requirements