The Advantage of Pucks for Shrink Sleeving

1. Consistent Shrink Sleeve Placement – Every Time

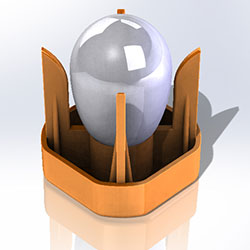

The blessing and curse of creative packaging is unique design. Marketing gurus love packaging with complex geometries and gimmicks, but automated production of these bottles, packages, and products can be an absolute nightmare. Shrink sleeving is an ideal solution to brand oddly-shaped goods, but alignment can be a major problem for packaging with extreme designs. Products conveyed using pucks can provide manufacturers with a new means for accurate shrink sleeve placement by ensuring a fixed-product position before application. It’s a simple solution to a complex placement problem that works every time.

2. Shrink Sleeve Under The Product

Shrink sleeving multiple products together for bulk purchases is an industry standard practice, but it can get complicated when you’re attempting to ensure the sleeve material is underneath several products simultaneously. Many companies turn to custom pucks to simplify the bulk sleeving process. Pucks are a simple cost effective solution that elevates products evenly to ensure that multi-pack products are fully surrounded on the top, bottom, and sides.

3. Stabilize Odd Form Bottles During Sleeve Application

Beautiful bottle shapes are packed with shelf appeal, but they can be an absolute pain to convey, fill, and wrap reliably. Custom-molded pucks are an easy-to-implement solution to stabilize even the most unwieldy of packaging. Pucks provide a simple and stable platform for shrink sleeving, ensuring a tipsy bottle won’t jam the line, mar the label, or potentially damage expensive production equipment.

4. Consistent Product Spacing Maximizes Heat Transfer

Line spacing is vital during the shrink sleeving process for a myriad of reason. Proper product spacing ensures optimal heat transfer and can minimize label distortion or marring. A custom-molded puck for shrink sleeving is a cost effective solution which eliminates all of these potential hazards easily.

5. Standard Product Position Eliminates Changeover

Line changeover is the bane of production worldwide. Changeover is a time-consuming and costly process that affects companies large and small. Advantage Puck exists to help manufacturers minimize the headache associated with changeover, and they help companies achieve that goal with a simple, cost-effective solution; a puck. Advantage Puck provides shrink sleeve users with the means to standardize variably-sized product position to eliminate most changeover associated with shrink sleeve systems. For additional information about how a custom puck from Advantage Puck can streamline your shrink sleeve system contact a member of the Advantage Puck Team today.

Need Pucks For Shrink Sleeving?

We’d love to speak with you.

Fill out the form below to speak with the APT team about your puck and product handling needs.

1. Consistent Shrink Sleeve Placement – Everytime

The blessing and curse of creative packaging is unique design. Marketing gurus love packaging with complex geometries and gimmicks, but automated production of these bottles, packages, and products can be an absolute nightmare. Shrink sleeving is an ideal solution to brand oddly shaped goods, but sometimes that just isn’t enough. Products conveyed using pucks can provide manufacturers with a new means to ensure that shrink sleeve placement is consistent on products with even the most abstract of designs.

2. Shrink Sleeve Under The Product

Shrink Sleeving multiple products together for bulk purchasing is an industry standard practice, but it can get complicated when you’re attempting to ensure the sleeve material is underneath the product. Many companies turn to custom pucks to simplify the bulk sleeving process. Pucks are a simple cost effective solution that elevates the product to ensure that the package is fully surrounded on the tops, sides, and bottom.

3. Stabilize Odd Form Bottles During Sleeve Application

Beautiful bottle shapes sell well, but they can be an absolute pain to convey, fill, and wrap reliably. Custom molded pucks are an easy to implement solution to stabilize even the most unwieldy of packaging. Pucks provide a simple and stable platform for shrink sleeving, ensuring that a tipsy bottle won’t jam the line, mar the label, or potentially damage expensive production equipment.

4. Consistent Product Spacing Maximizes Heat Transfer

Line spacing is vital during the shrink sleeving process for a myriad of reason. Proper product spacing ensures optimal heat transfer and can minimize label distortion or marring. A custom molded puck for shrink sleeving is a cost effective solution that eliminates all of these potential hazards easily.

5. Standard Product Position Eliminates Changeover

Line changeover is the bane of production worldwide. Changeover is a time consuming and costly process that affects companies large and small. Advantage Puck exists to help manufacturers minimize the headache associated with changeover, and they help companies achieve that goal with a simple cost effective solution; a puck. Advantage Puck provides shrink sleeve users with the means to standardize variably-sized product position in order to eliminate most changeover associated with shrink sleeve systems. For additional information on how a custom puck from Advantage Puck can streamline your shrink sleeve system contact a member of the Advantage Puck Team today.

Need Pucks For Shrink Sleeving?

We’d love to speak with you.

Fill out the form below to speak with the APT team about your puck and product handling needs.